Scrapbooking is an artistic attempt that allows individuals to creatively preserve their memories using several decorative elements. Clear stamps, also known as photopolymer or acrylic stamps, are an basal tool in the scrap-booker’s armoury. These stamps are prized for their preciseness, versatility, and ease of use. In this comprehensive blog post, we will delve into the production-oriented manufacture of scrap-booking clear stamps, exploring the materials, processes, and innovations that bring these indispensable crafting tools to life.

What is Clear Stamps?

Clear stamps are made from a transparent, pliable material that allows crafters to see precisely where they are stamping. This clarity makes it easier to position the stamp accurately on the page, resulting in more professional-looking results. Clear stamps are used with acrylic blocks, which provide a rigid surface to press the stamp evenly onto the paper.

Materials Used in Clear Stamp Production: The Core Ingredients

The primary material used in the manufacture of clear stamps is photopolymer resin. This material is chosen for its excellent ability to capture fine details, its durability, and its flexibility. Here are some fundamental components involved in the production process:

-

Photopolymer Resin

Photopolymer resin is a light-sensitive material that hardens when exposed to ultraviolet (UV) light. This attribute makes it ideal for creating detailed and precise stamps. The resin must be of high quality to guarantee that the stamps can withstand repeated use without losing their shape or clarity.

-

Base Materials

The base material for clear stamps is typically a clear sheet of plastic or acetate. This base provides the necessary support for the photopolymer resin during the production process and ensures that the stamps maintain their shape.

-

UV Light Source

A UV light source is essential for curing the photopolymer resin. The light causes a chemical reaction in the resin, hardening it into the desired shape. The intensity and duration of UV exposure are critical factors in achieving the perfect balance between flexibility and durability in the finished stamp.

-

Adhesive and Cling Foam

Once the stamps are cured, they are often backed with a layer of adhesive and cling foam. This backing allows the stamps to adhere temporarily to acrylic blocks and be easily removed and repositioned.

The Production Process of Clear Stamps: Let’s know the story behind it

The production of clear stamps involves several meticulous steps, each designed to ensure the highest quality and precision. Let’s explore each stage in detail:

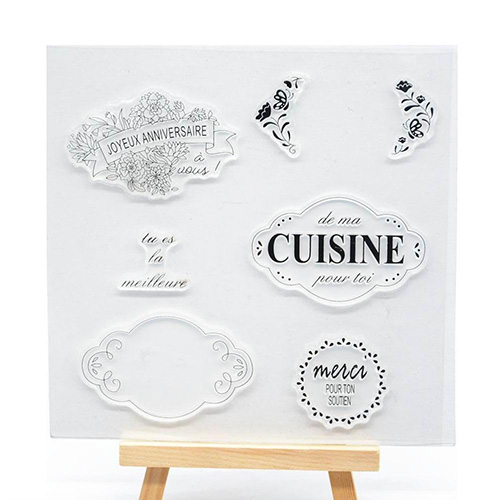

Fig: Clear Stamp production process in Glitz Art and Craft Co., Ltd

.Design Creation

The first step in producing clear stamps is designing the images or patterns to be stamped. Designers use specialized software to create intricate and detailed artwork. The designs can range from simple shapes and letters to complex images and patterns. Once the design is finalized, it is transferred to a transparent film or digital medium.

.Photopolymer Plate Preparation

The transparent film with the design is placed over a sheet of uncured photopolymer resin, which is supported by a base material. The film acts as a mask, allowing UV light to pass through only in the areas where the design is present.

.UV Exposure

The photopolymer resin sheet is exposed to UV light. The UV light passes through the transparent areas of the film, hardening the resin in those regions. The areas shielded by the design on the film remain uncured. This step requires precise control over the duration and intensity of the UV exposure to ensure that the details of the design are accurately captured.

.Washing and Curing

After UV exposure, the uncured resin is washed away, leaving behind the hardened design. The sheet is then subjected to a secondary curing process to ensure that the remaining resin is fully hardened. This secondary curing typically involves additional UV exposure or heat treatment.

.Cutting and Trimming

The cured photopolymer sheet is cut into individual stamps. Each stamp is carefully trimmed to remove any excess material and to ensure clean edges. This step is crucial for ensuring that the stamps produce sharp and precise impressions.

.Backing Application

Many clear stamps are backed with a layer of adhesive and cling foam. This backing allows the stamps to stick to acrylic blocks during use. The backing must be applied evenly to ensure that the stamps can be easily repositioned and reused.

.Quality Control

Quality control is a critical step in the production process. Each stamp is inspected for defects, such as air bubbles, incomplete curing, or imperfections in the design. Stamps that do not meet the quality standards are discarded.

.Packaging

The final step is packaging the stamps. Stamps are typically sold in sets, which are packaged in clear plastic sleeves or boxes. The packaging often includes a printed image of the stamp designs, making it easy for customers to see what is included in the set.

.Innovations in Clear Stamp Manufacturing

The manufacture of clear stamps has evolved significantly over the years, with advancements in materials and technology improving both the quality and efficiency of production. Here are some notable innovations:

.Enhanced Photopolymer Resins

Advancements in photopolymer chemistry have led to the development of resins with improved durability, flexibility, and clarity. These enhanced resins produce stamps that can withstand repeated use without degrading in quality.

.Digital Design and Laser Engraving

Digital design tools have revolutionized the way stamp designs are created. High-resolution digital files ensure that even the finest details are accurately reproduced. Laser engraving technology has also been integrated into the production process, allowing for even greater precision in creating intricate designs.

.Automated Production

Automation has significantly increased the efficiency of clear stamp production. Automated UV exposure units, washing systems, and cutting machines streamline the process, reducing production time and minimizing errors.

.Environmentally Friendly Practices

Manufacturers are increasingly adopting environmentally friendly practices, such as using non-toxic photopolymer resins and recycling waste materials. These practices help reduce the environmental impact of clear stamp production.

.Customization and Personalization

Advancements in digital printing and cutting technology have made it possible for manufacturers to offer customized and personalized clear stamps. Customers can upload their designs, which are then transformed into custom stamps. This trend has expanded the creative possibilities for scrapbookers and other crafters.

Leading Manufacturers of Clear Stamps: The Key players

Various companies are renowned for their high-quality clear stamps. These manufacturers have established themselves as leaders in the industry through their commitment to innovation, quality, and customer satisfaction. Here are few of the top names in clear stamp manufacturing:

-

Hero Arts

Hero Arts is a pioneer in the stamp manufacturing industry, known for its high-quality clear stamps and commitment to sustainable practices. The company offers a wide range of designs, from simple shapes to intricate patterns, and is celebrated for its innovative products and excellent customer service.

-

Lawn Fawn

Lawn Fawn is a well-loved brand in the crafting community, known for its whimsical and playful stamp designs. Their clear stamps are made from high-quality photopolymer resin and are designed to work perfectly with their range of coordinating dies and inks.

-

Avery Elle

Avery Elle is a newer player in the stamp manufacturing industry but has quickly gained a reputation for producing high-quality clear stamps. Their designs are fresh and modern, appealing to a wide range of crafters. Avery Elle is also known for its innovative packaging and product presentation.

Challenges in Clear Stamp Manufacturing: hurdles in the road

Despite the advancements and innovations in clear stamp manufacturing, the industry faces several challenges. Addressing these challenges is crucial for maintaining quality and meeting the growing demand for these products.

-

Material Quality Control

Ensuring the consistent quality of photopolymer resin is essential for producing durable and detailed stamps. Variations in resin quality can lead to defects such as air bubbles, incomplete curing, and reduced stamp longevity.

-

Preciseness and Detail

Achieving the high level of precision required for intricate stamp designs is challenging. Any imperfections in the design or production process can result in stamps that do not produce clean impressions.

-

Environmental Issue

The production of photopolymer resin and the use of UV curing technology have environmental implications. Manufacturers must balance the need for high-quality materials with sustainable practices to minimize their environmental footprint.

-

Market Competition

The clear stamp market is highly competitive, with many manufacturers vying for the attention of crafters. Staying ahead of trends and continuously innovating is essential for maintaining a competitive edge.

-

Customization Demand

The growing demand for customized and personalized stamps presents both an opportunity and a challenge. Manufacturers must develop efficient processes for producing custom stamps while maintaining quality and keeping costs manageable.

The Future of Clear Stamp Manufacturing: What the Future holds

The future of clear stamp manufacturing looks promising, with several trends and advancements on the horizon:

.Sustainable Practices

As environmental concerns continue to grow, manufacturers will increasingly adopt sustainable practices. This includes using eco-friendly materials, reducing waste, and implementing energy-efficient production processes.

.Technological Advancements

Advances in digital printing, laser cutting, and automation will continue to enhance the precision and efficiency of clear stamp production. These technologies will enable manufacturers to produce even more detailed and intricate designs.

.Increased Customization

The trend toward customization and personalization will likely continue to grow. Manufacturers will invest in technologies that allow for efficient production of custom stamps, catering to the unique needs and preferences